-

18680 Employees

-

4696 million EUR Sales 2024

-

394 million EUR R&D Expenses

-

120 Years of company history

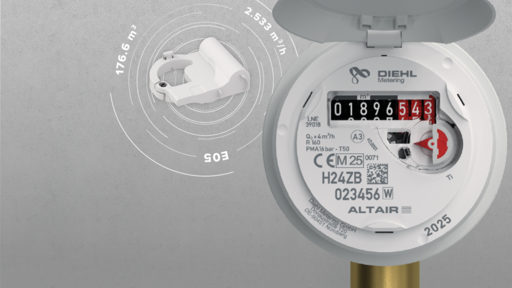

Diehl Group

Tradition goes Future!

Diehl Stiftung GmbH & Co. KG is a globally active German technology enterprise headquartered in Nürnberg. Our broadly diversified product range comprises various business fields in different industrial sectors. With approx. 18,700 employees worldwide, the long-established Diehl company generates annual sales of 4.7 billion euros.

About us